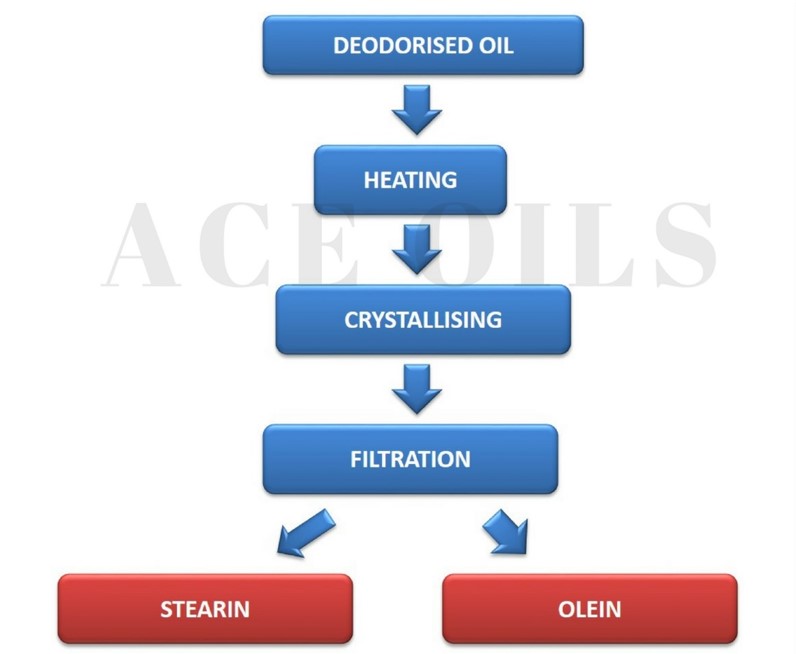

DRY FRACTIONATION

To produce high quality olein and stearin

Ace Oils Dry Fractionation plant is custom designed to allow you to achieve selective crystallisation of different tryglycerides in edible oil. Ace Oils Dry Fractionation plant you can count on producing stable and filterable crystals giving you a product to fit your standards and quality requirements.

Ace Oils Dry Fractionation system is designed to produce crude, pre-treated or RBD palm oil. This makes the entire process simpler with no environmentally hazardous waste produced. The process consist of 5 stages

- Heating the feed oil

- Formation of crystal by controlled cooling

- Crystal growth

- Maturation of crystals

- Filtration to separate olein and stearin

Crystallisers are fitted with double row of circular cooling coil and a variable speed multi-stage agitator. Crystalliser are designed with a large cooling surface area, this ensures that the build-up of crystals does not occur. The variable speed agitator contributes to gentle agitation, this keeps the oil mass moving without allowing stagnation close to the cooling coil.

If you wish Ace Oils can also equip your Dry Fractionation system with a computerised distributed control system and tailormade to your requirements. This combines all operations into a fully automated unit. We can accomplish filtration either with a Rotary Drum Vacuum filter or a membrane filter press.

Filtration is effected by vacuum created by vacuum pump & the filtrated is collected in a receiver provided with a moisture trap. The vacuum is generated by water ring vacuum pump. The vacuum forces creates continuous & constant suction head under the submerged portion at 200C to 250C of slurry. The vacuum sucks olien into the receiver. Stearin forms unform layer on the filter cloth fixed on rotary drum. As the drum rotates progressive drying takes place at the end of revolution. The cake is backblwon with air and with the help of scrapper blade, the stearin is discharged in collecting tank, which is provided with steam heating arrangement for melting the stearin, and then transported to storage tank by pump. The Olein in the form of filtrate is collected in the receiver and then transported to storage tank.