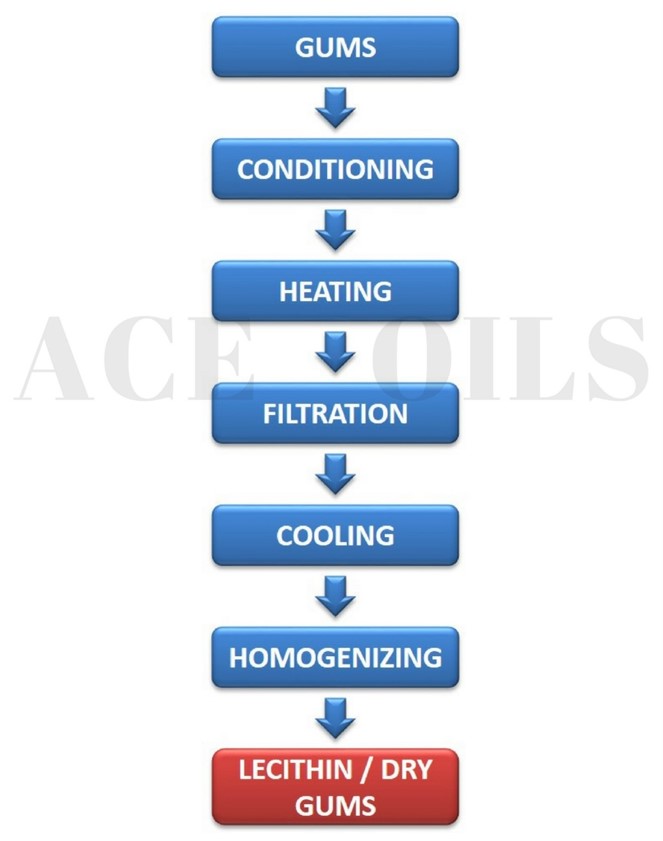

LECITHIN/GUM DRYING PLANT

Wet gums obtained by water degumming of crude Soya oil are rich in phosphotides. Commercial lecithin can be obtained by careful processing of these gums to remove moisture.

Wet gums (30-40% moisture) are preheated in specially designed mixer

(FT-1/FT-2) The preheated gums are transported into a Heat Exchangers through screw pumps with variable speed. The heat exchangers are specially designed wherein gums are heated under vacuum with very low time of contact. This prevents heat sensitive precious material from darkening.

The heated products are discharged into a vapour separator which is under vacuum. Water vapour separated is sucked into a barometric condenser.

The moisture free phosphotides (Lecithin) are then transferred into another Heat Exchanger where the products are cooled. The cooled products are then transferred to blending / conditioning tanks where he product is standarised before packing.